The $100,000 Cabinet Question…

Is the Quality of an Italian Luxury Kitchen Worth the Investment Over US Custom?

When investing in a high-end kitchen, homeowners often face a critical decision: commission local US custom cabinetry or import a meticulously engineered system from a European powerhouse, particularly Italian luxury brands.

While both options promise a "custom" look, the reality is they represent two fundamentally different approaches to construction, materials, and precision. It’s not just about aesthetics; it’s about engineering, longevity, and factory perfection.

The Philosophical Divide: Craftsmanship vs. Engineering

The core difference lies in their approach to manufacturing:

🇺🇸 US Custom: This model relies on craftsmanship. A local shop often uses traditional face-frame construction and solid wood, building cabinets largely by hand or on-site. It’s a highly skilled, adaptable, and artisanal process.

🇮🇹 Italian Luxury (e.g., Arclinea, Boffi, Poliform, CESAR): This model relies on precision engineering. Kitchens are built in massive, highly automated factories using frameless construction and high-tech engineered materials. They are furniture-grade systems designed for exact assembly anywhere in the world.

The Anatomy of Quality: Materials and Construction

1. Frameless vs. Face-Frame Construction

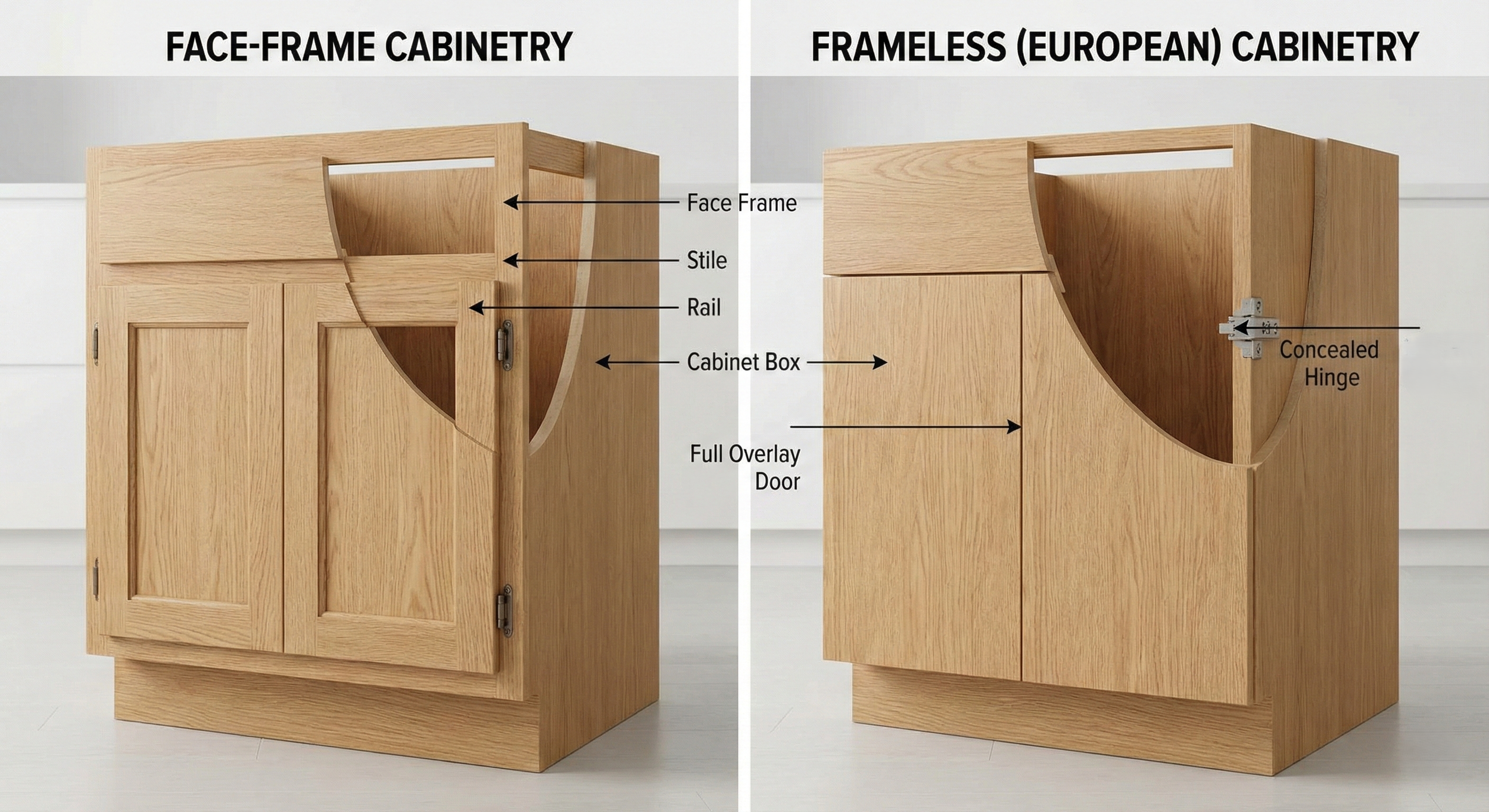

Face-Frame vs Frameless

This is the most significant structural difference.

US Face-Frame: This construction involves a solid wood frame attached to the front of the cabinet box. This adds structural rigidity but results in less accessible storage space (due to the frame encroaching on the opening) and a more traditional, visible look.

Italian Frameless (Euro-Style): The door mounts directly onto the box, eliminating the face frame entirely. This offers maximum interior storage and creates the sleek, uninterrupted, and modern European aesthetic. It requires incredibly precise engineering—a slight error in alignment is far more noticeable than in a frame-mounted system.

2. The Power of Engineered Materials

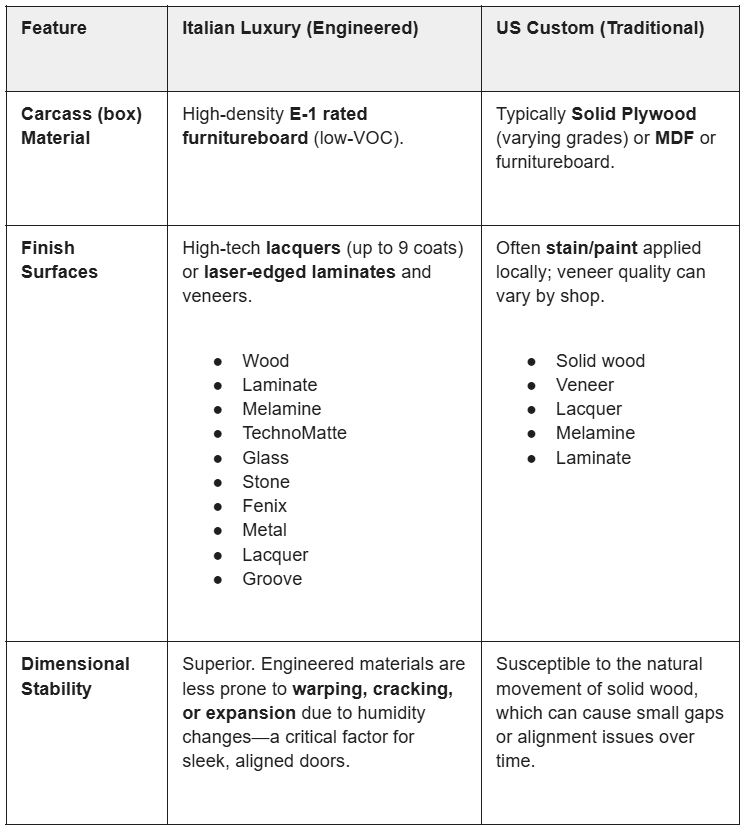

While US custom builders often tout solid wood as superior, Italian manufacturers leverage high-quality engineered materials for superior stability and finish.

Matrix of Engineered Materials vs Traditional

3. Hardware: The Hidden Engine

Italian firms standardize (All mechanical hardware is manufactured by a small group of suppliers) on the world's best hardware—brands like Blum, Grass, Hettich or Salice. This isn't just a drawer slide; it's a precisely engineered storage mechanism.

Integrated Motion: Soft-close drawers and hinges are standard. Look for specialized mechanisms like heavy-duty, synchronized slides for wide drawers and pocket door systems designed to handle thousands of cycles without failure.

Consistency: Because the entire system is designed around specific hardware dimensions in the factory, the operation is smooth, silent, and flawlessly consistent across every cabinet unit.

The Verdict on Value: Long-Term ROI

Is the possibly higher price tag worth it? For the homeowner prioritizing a truly modern aesthetic, uncompromised precision, and the confidence of a system built to exacting international standards, the answer is often yes.

While a US custom kitchen offers adaptability and local craftsmanship, an Italian luxury kitchen delivers furniture-grade perfection and superior dimensional stability. You are not just buying cabinets; you are buying a complete, highly refined, and durable design system—a factor that often translates to a better Return on Investment (ROI) when the time comes to sell your luxury home.

The Final Outcome: Precision Creates Pure Design

The investment in European engineering yields a result that goes beyond durability and smooth operation: flawless aesthetics.

In an Italian luxury kitchen, the precision hardware and engineered materials ensure:

Perfect Alignment: Doors and drawers sit flush with minimal, precise gaps. There are no exposed frames or hinges to interrupt the clean lines. This is the very definition of modern, minimalist design.

Seamless Surfaces: The high-tech lacquer finishes and laser-edged laminates create truly monolithic surfaces that reflect light uniformly. This uniformity is nearly impossible to replicate with localized, hand-applied finishes.

The Integrated Look: Because every component—from the carcass to the pull-out pantry—is designed as part of a factory system, the final kitchen feels less like a collection of separate cabinets and more like a single, cohesive architectural volume.

Consistency of finishes: The hallmark of factory-finished Italian cabinetry is the unmatched consistency of its finishes, achieved through highly automated, controlled production environments. This process guarantees that every component, from door to drawer front, maintains the exact same color saturation, sheen, and textural depth, even years apart. This precision eliminates the common risks of color-shift and batch-to-batch variation, ensuring a truly unified and monochromatic appearance throughout the entire kitchen.

The take-away is simple: When you choose Italian luxury, you are paying for the certainty of perfection. You are eliminating variables associated with local craftsmanship and embracing a system where engineering dictates the flawless execution of high-end design. The true value lies in the marriage of unparalleled quality and pure, uncompromising style that will define your home for decades.